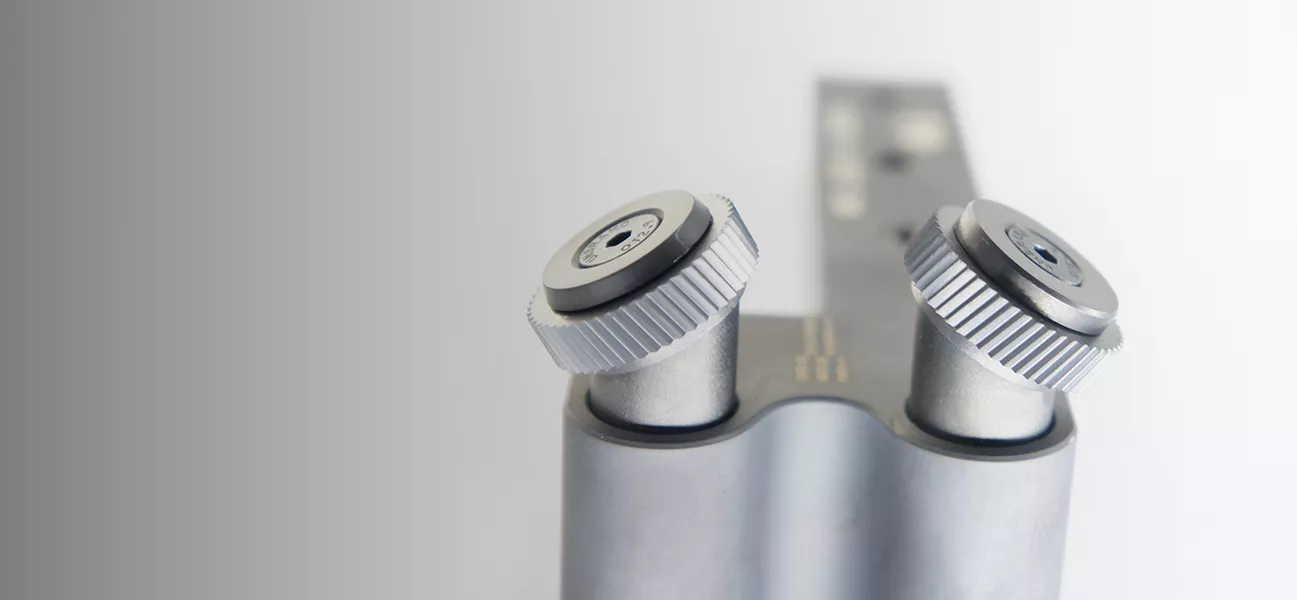

The Zahn® knurling product line was designed as a high-quality alternative to commercially available products.

In addition to the standard sizes, it includes special knurling profiles and customized creations.

Each knurl is built following procedures of maximum precision and with the use of selected high quality steels.

Applications

Uses in the mechanical, automotive, aerospace and watchg industries in accordance with the knurling standards DIN 82 and UNI 149

Knurling tools

All our tool holders are built with high quality steels, heat treated and coated.

They are entirely designed and made in Italy.

Each appliance is equipped with easy-to-consult instructions for use.

Front knurling

Front knurling, if less than 3 mm, can be done with a parallel knurling.

If the thickness of the knurling is greater, up to 8 mm, a conical knurling must be used, to be specially constructed.

Form knurling

The form knurls are made in HSSE-PM in order to obtain high class and quality products.

Our knurls are ground and lapped, therefore equipped with a smooth surface for excellent material flow. This allows for an increase in the duration of the knurl itself and a shorter machine changeover time.

Technical consultancy

Do you need advice and help to choose the solution that best suits your needs?

We'll think about it!

The entire Manigley Italia technical department, with speed and thanks to the decennial experience gained, is ready to assist you in the choice, application and machining with the tools distributed by us.

Current legislation

There are several regulations.

The Italian one is UNI 149 while the German one is DIN 82.

Both have similarities. For example, both references may appear on technical drawings.

It is always necessary to find this normative reference on the drawing. Should it be missing, our technical office can work directly on existing projects and offer specialized consultancy.