The threading process is used to make a thread on the external cylindrical surface of a metal piece.

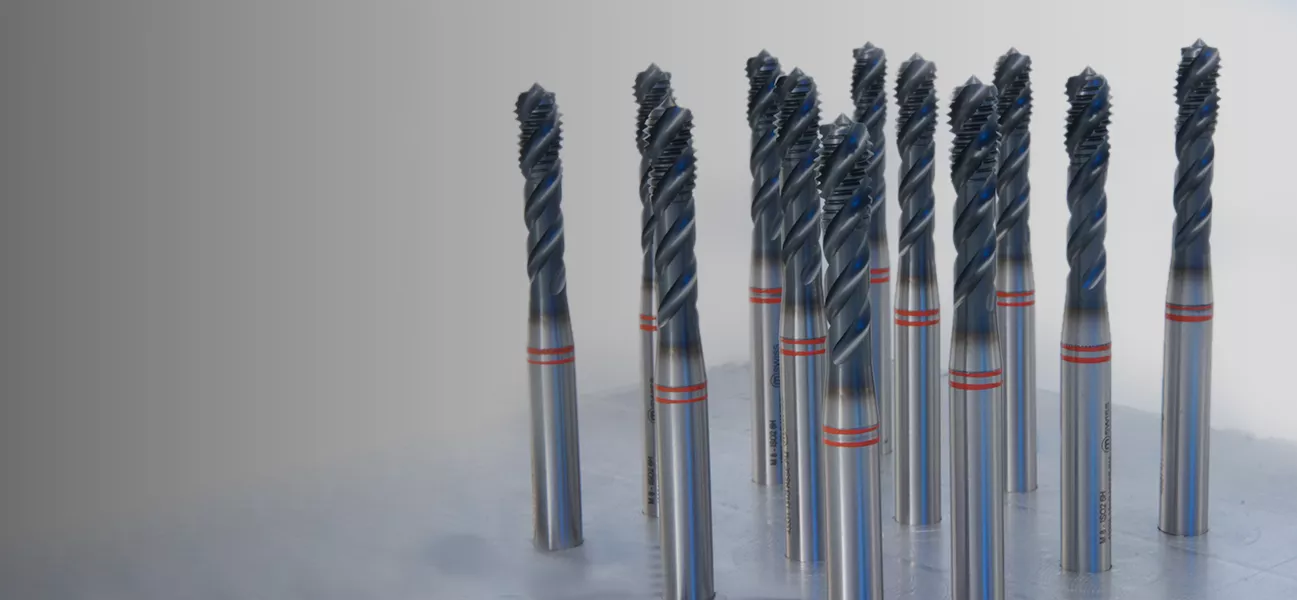

Our threading tools are divided into taps and thread mills.

The taps differ between chip removal taps and forming taps.

Discover features, processes and advantages!

Threading process

Fields of threading application

Employments in the mechanical, automotive, aerospace, eyewear and watchmaking industries.

The threading can be done with taps or carbide thread mills.

Thread

The GAS thread is characterized by a 55° tooth angle.

We can make a wide range of taps and thread milling cutters that cover all of our customers' needs.

Metric thread

Metric thread is the most common. In our catalogs you will find a wide range of taps and thread milling cutters for the toughest metals capable of ensuring the best possible performance.

What distinguishes it from other products on the market? The high quality, the accurate presentation of the product and the customer service; cared for in every detail.

Our range of double ring taps also offers the possibility of decreasing the impact of the tool on the cost of the piece.

American thread

The American thread (UNC, UNF, UNJ, UNEF) is more present in the aerospace sector.

We guarantee high quality standards for machining tough steels and exotic alloys.

Technical consultancy

Do you need advice and help to choose the solution that best suits your needs? We'll think about it!

The entire Manigley Italia technical department, with speed and thanks to the decennial experience gained, is ready to assist you in the choice, application and machining with the tools distributed by us.

Norm

Our range of carbide thread milling cutters are built to suit all customer requirements, with both central and lateral coolant holes.

Our new 2xD and 3xD Mini Series is designed for smaller threads and materials such as titanium alloys, stainless steels and hardened steels up to 45 HRc.